New Product Design & Build Services for OEMs

Whether you’re a startup or an established OEM, partnering with Owens Design will enable you to bring your products to market on accelerated schedules to capture your opportunity, while achieving the level of quality you need.

Owens Design will help transform your IP into production-ready prototypes that meet challenging deadlines with the lowest risk possible.

All of this is possible by taking advantage of our prototype design and build service and volume manufacturing option.

Startups

With Owens Design as your partner, you will accelerate time-to-market while ensuring the highest quality standards – which is critical for bridging the valley of death. You will be able to leverage the Owens Design depth of expertise in semiconductors, medical devices, EV batteries, metrology, laser process development, and more.

Owens Design provides the extensive new product development (NPD) expertise and domain knowledge to productize your IP and deliver production-ready tools on accelerated schedules. Owens will provide an “instant-on” senior engineering and manufacturing team to complement your internal team without delays when hiring and training new staff so you can keep your engineers focused on developing and optimizing your core IP and leave the rest to Owens. You can also avoid spending on manufacturing infrastructure by leveraging a mature manufacturing team trained on the highest requirements for semiconductor and biotech equipment.

Startup OEMs also find value in leveraging the Owens Design supply chain that has been developed over the last 40 years, especially access to suppliers that don’t typically work with startups.

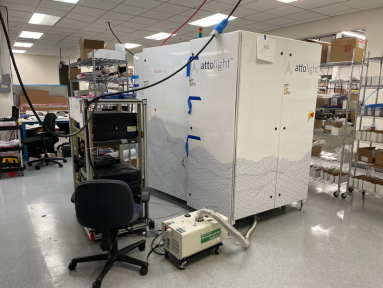

Startup OEM Case Studies

Established OEMs

Owens Design partners with established OEMs when you want to extend your bandwidth, especially when you need to accelerate development of ancillary or non-core products on your roadmap.

Our team follows a phased process to optimize tradeoffs and reduce risk while designing and building prototype systems. Owens Design also provides volume manufacturing, including managing the design of customer specials and continuous improvement initiatives. Established OEMs also appreciate our ability to keep BOM cost down by using Owens Design as a non-recurring engineering (NRE) investment, which can be amortized as R&D. We can also assist with the transfer to your contract manufacturer if your strategy calls for it.

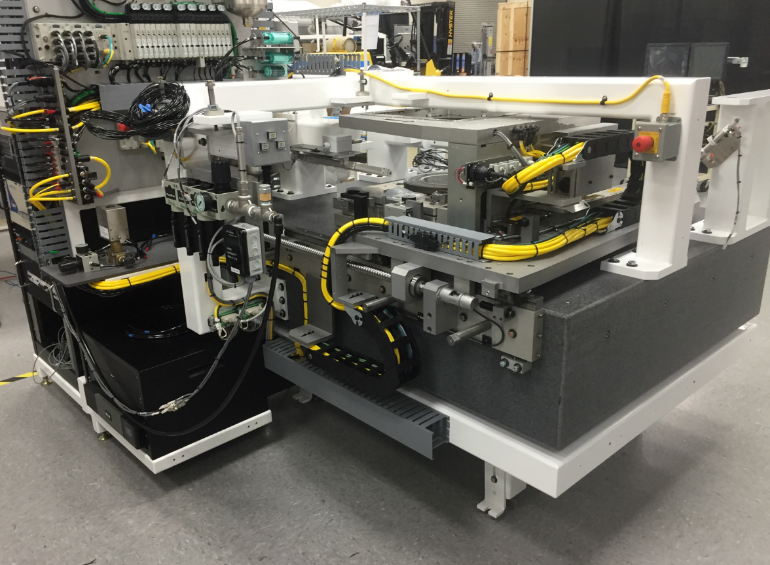

Established OEM Case Studies

How We Work

Phase 0:

Mutual Qualification

Phase 0:

Mutual Qualification

Evaluate technical and business alignment on both sides prior to launching a project. If alignment isn’t right, we often help our prospective clients find a better fit.

Phase 1:

Requirements

Phase 1:

Requirements

Align on function, timeline and cost, with proof of concept for high-risk areas as needed.

Phase 2:

Design & Build

Phase 2:

Design & Build

Completion of your production-ready prototype system.

Phase 3:

Volume Production

Phase 3:

Volume Production

Repeat builds of the system, with continuous improvement over time.