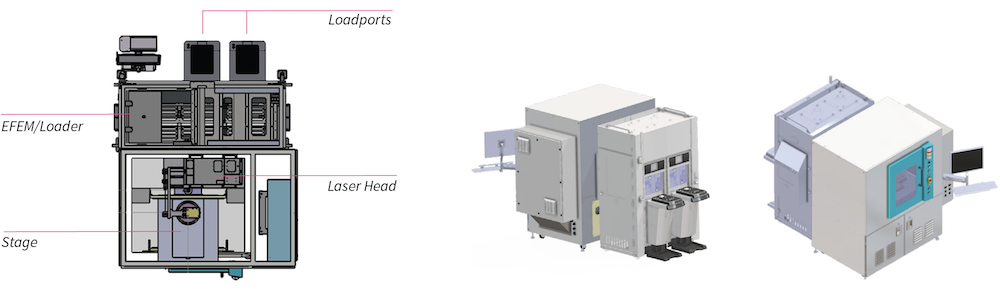

Automated Laser Wafer Platform

Customizable Laser Processing with Wafer Handling Automation

The Automated Laser Wafer Platform can be configured for your specific manufacturing needs to fit the right laser source, beam delivery, motion systems, wafer-handler and integration of custom product fixtures, making this an extremely versatile machine for manufacturing your product. As your product evolves, our machine can be reconfigured giving you critical versatility needed during pilot and ramp up phases.

Wafer Handling Automation

Various wafer handling automation solutions are available including standard wafer handlers, such as standard Equipment Front-End Modules (EFEMs) as well as fully custom wafer handlers. Both round and rectangular parts can be processed including 150-300mm wafers and solar M6-M12 form factors. The EFEMs have a variety of features including cassette handling, barcode scanning, pre-alignment, load/unload and communication with factory automation via a variety of interfaces including SECS/GEM, OPC-UA and other common protocols.

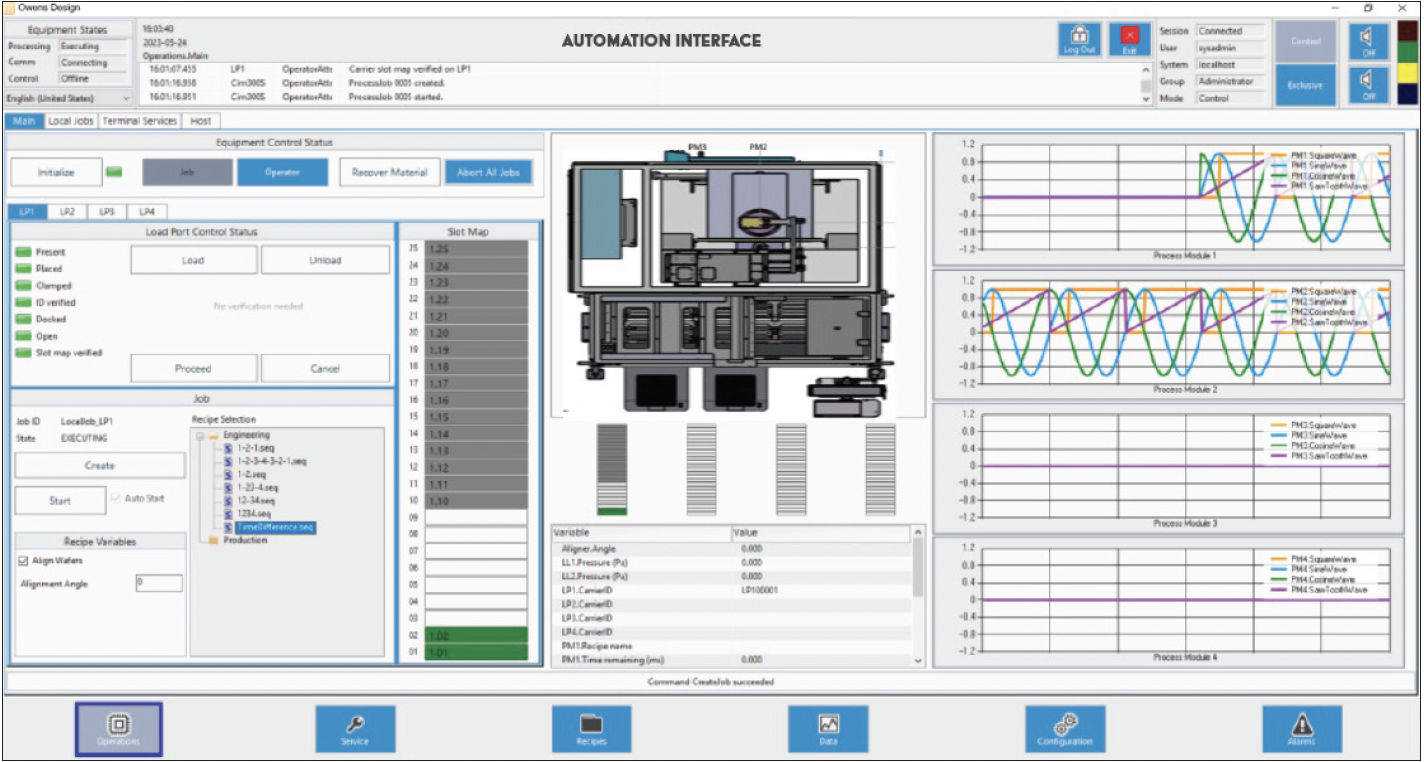

Flexibility, Precision & Control Meets Ease of Use

To make the workflow simple and intuitive, our automation solution includes a single Human-Machine Interface (HMI) to control the entire machine, ensuring that one process recipe can manage all process parameters.

Streamlined Automation

Our HMI allows for operators to simply choose a recipe, load a cassette of wafers and run the tool. Included in the HMI are:

- Factory automation (SECS/GEM, OPC-UA, and others available)

- Wafer scheduling and coordination

- Automated data logging

- User access control

- Maintenance routines

- Real time analysis

We use the latest communication protocols, and industry standards to ensure reliability and high throughput.

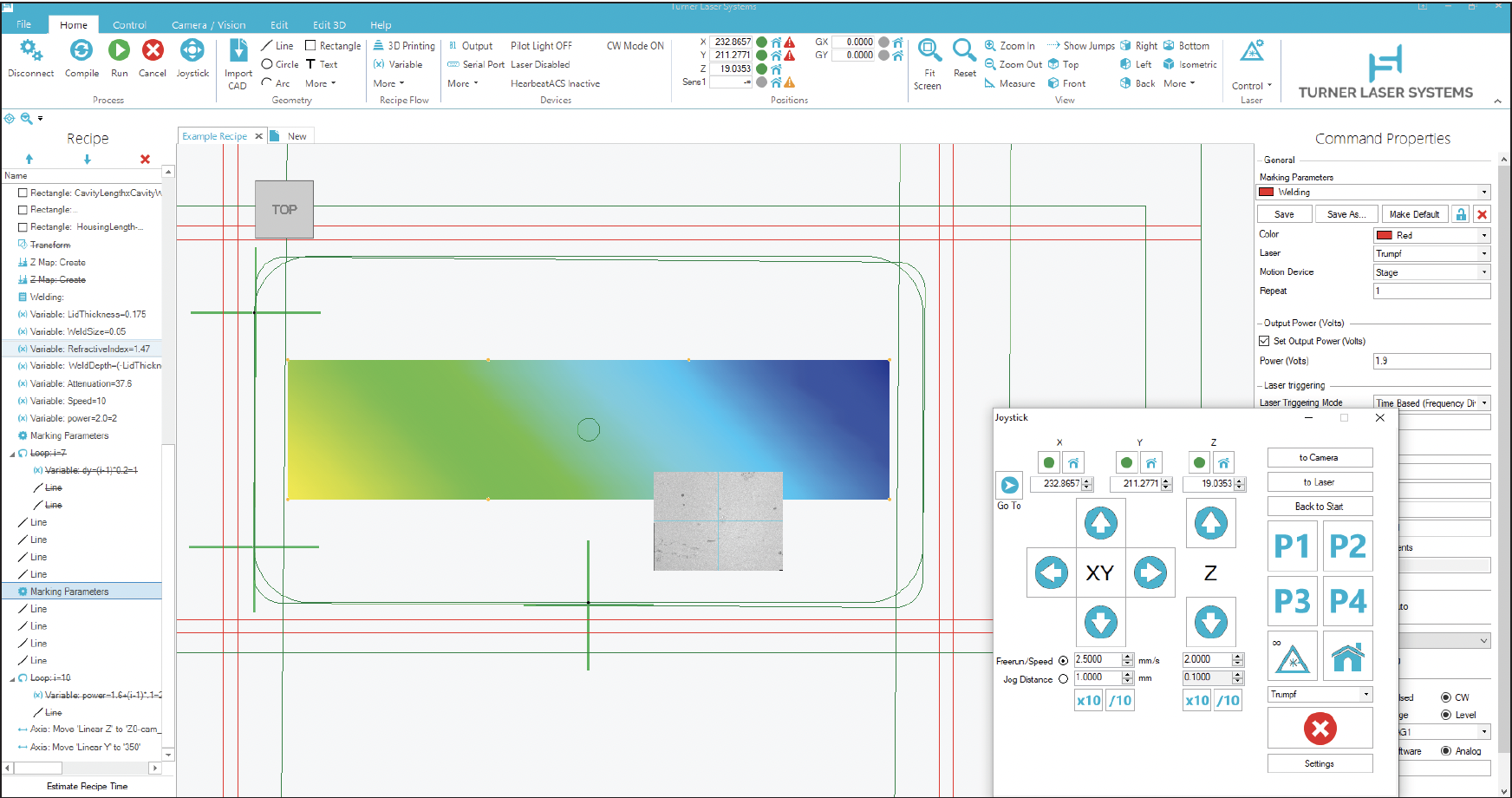

Flexible Controls for Laser Processing

For creating and editing new laser processing recipes engineers are given a powerful recipe editing interface, that is a full 3D CAD CAM platform. This includes key features such as:

- CAD file import (e.g. dxf, dwg, gerber, STL, STEP)

- CAM features such as path generation and lead in/out

- Recipe library and process development tools

- Automatic vision alignment

- 3D part mapping

- Process data logging and file import

- Math & logic features for advanced process logic control

- Many other features for optimizing process control