4 Reasons Custom OEM Automation Projects Fail

From managing projects in-house to changing product specs mid-stream, here are some common – and costly – mistakes that can derail OEM equipment design and build projects.

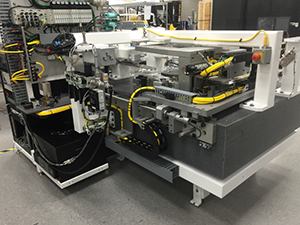

Original equipment manufacturers (OEMs) produce equipment for use in manufacturing facilities (e.g. semiconductor fabs for microchips). The design and build of this equipment is sometimes outsourced for strategic reasons. While the type and complexity of new OEM equipment design projects vary widely across industries, there are some common pitfalls.

Here are four scenarios that can doom an OEM design and build project to unnecessary complications and even failure.

1. Trying to Do It All In-House

Trying to handle your entire project in-house can be a costly mistake. For startup OEMs, it can be tempting to build out a team internally to “keep costs low.” This typically costs more, takes longer, and suffers from a lack of expertise outside the specialties of the in-house engineers.

Mature OEMs should consider outsourcing to allow their team to focus on their core products and increase their capacity without growing their staff. Outsourcing also frees you from the complexities of your organization and may inject new ideas to differentiate your product.

While most companies require multiple iterations, an experienced outsourcing partner can dramatically shorten the schedule and reduce cost by developing a shippable product the first time – this allows you to focus more on your internal IP.

2. Over Designing or Getting Caught Up in the Minutiae

Many internal engineering teams get caught up in the minutiae of the design process while losing sight of the goal. Beware of missing the (automation) forest for the trees.

While it’s imperative to ensure high quality in the details, it’s also critical to keep the big picture in mind. Spending too much time in the weeds can delay the progress and obscure the overall objective. Outsourcing the design and build process to an expert team of engineers frees up the OEM engineering team to work on higher value work.

3. Using an Integrator Instead of an Engineering Firm

Some OEMs make the mistake of choosing an integrator for their project instead of a design firm. The difference? An integrator buys parts off the shelf and assembles them, while an equipment design and build firm develops a customized solution to optimize your product.

Utilizing the wrong partner can lead to a lack of product development expertise and a product that falls short of expectations. Choosing an engineering design firm with deep expertise in your industry helps ensure the project’s success while relieving internal engineering teams of the heavy lifting for the boring stuff.

4. Changing the Product Definition Mid-Stream

It can be tempting to make major changes to your equipment project when a significant new customer emerges with a request for something a little different. It’s a common mistake that can delay time-to-market and lead to an excessively costly product. These requests are best addressed in post-launch/ongoing development.

Utilize Expert Design & Build Knowledge with a Design & Build Partner

Designing and building successful OEM equipment requires careful planning, collaboration and expertise. By avoiding these common mistakes, OEMs ensure that their project is completed on time, within budget, and with high-quality, high-value results.

Collaboration with experienced design and build experts enables OEMs to focus on what they do best. The right partner will have experience in your industry, be well versed in market trends, and have a clear strategy for keeping your project from getting stalled in the valley of death.

At Owens Design, every member of our engineering team is deeply experienced in design build projects – having completed as many as 40 of them over a decade of collaboration with OEMs across industries, including laser, semiconductor, emerging technologies, and many others. Speak to one of our OEM equipment experts to learn more about avoiding the common pitfalls of design and build projects.