Case Study: Scaling EV Battery Production While Maintaining Laser Cutting Precision

Obtaining automated, precise cutting on a critical, fragile layer at high production volumes

An EV battery manufacturing startup needed to scale their production volume to meet the growing demands of their customers.

A critical step of their innovative product required precise cutting of a delicate layer in the battery stack. The manufacturer had developed a laser process in their R&D lab but required optimization to significantly improve quality, precision and throughput, and be integrated into a high-volume production tool.

Meeting these unique EV battery quality control requirements was paramount to their go-to-market strategy. Failure to meet them would result in lower yields or subpar battery performance and could even lead to catastrophic battery failures. Establishing a reputation for delivering high-quality products in this highly competitive market was essential for the success of this new offering.

Achieving optimal throughput was a crucial factor in determining the cost of the batteries and the ability to meet production volume targets. Falling short of these targets could instill doubt in the market regarding the scalability of the technology, leading to hesitancy in adopting the product. As a result, balancing both quality and throughput was vital in ensuring customer confidence, market adoption, and the overall success of the battery company in a fiercely competitive market.

To achieve their quality and production goals, the EV battery manufacturer required external support from both laser cutting and automation experts.

The Challenges

The EV battery product and manufacturing requirements presented major challenges for the laser process and the high-volume manufacturing equipment:

- The thin and brittle composition of the material made it susceptible to damage, especially with the high-speed handling needed to meet production throughput requirements

- Standard die cutting technologies could not meet the quality requirements and conventional laser cutting technologies created thermal damage, micro-cracks, and sticky debris, all of which could decrease product yield and reliability

- Meticulous optimization of the laser process was required to ensure impeccable cutting quality, characterized by clean and precise kerf, minimal heat-affected-zone, and the absence of micro-cracks

- The equipment required custom methods to hold and align the materials, support the laser process, and provide ease of maintenance

- Automated cleaning mechanisms were needed, capable of removing the debris generated by the laser cutting process without damaging the material

- Both cutting and cleaning processes had to be efficiently executed to achieve high throughput manufacturing in line with the desired production targets

- The early-stage nature of the product technology meant that the battery’s form factor was subject to change, introducing further obstacles for both the process and the equipment involved and requiring adaptability to accommodate modifications

The Solution

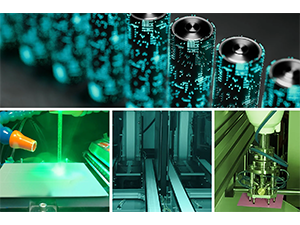

Turner Laser Systems and Owens Design partnered together to develop and incorporate a manufacturing-ready process into a production-ready laser system. The semi-custom laser platform was integrated quickly into a custom, fully automated system to handle and clean the delicate parts.

The laser expertise of Turner Laser Systems and the manufacturing automation experience of Owens Design combined to deliver a complete solution that overcame all of the EV battery manufacturer’s challenges.