4 Stages of Custom Automation Solutions to Help Scale Your Production Line

Once a company or startup has succeeded in developing a working prototype and market for the new product, the next question is “How do I scale my production?” It’s not an easy transition from prototype development to go for full production. To shed some light on the matter, we’ve identified several levels of automation that are suitable for different situations:

- Manual Workstations

The simplest method, also easiest to scale. Scaling up manual production usually just takes more workstations and staff. Certain operations that require a fine level of hand-and-eye coordination such as precision wiring, PCB rework and some medical device assembly don’t make much sense automating. Labor costs also play a factor here.

- Manumation Stations

The manufacturing process step at a manumation station usually is difficult for a human operator to do ergonomically or quickly. Imagine a station where were multiple screws can insert all at the same time. Parts are still manually loaded and unloaded. Usually a good first step for automation in a production environment.

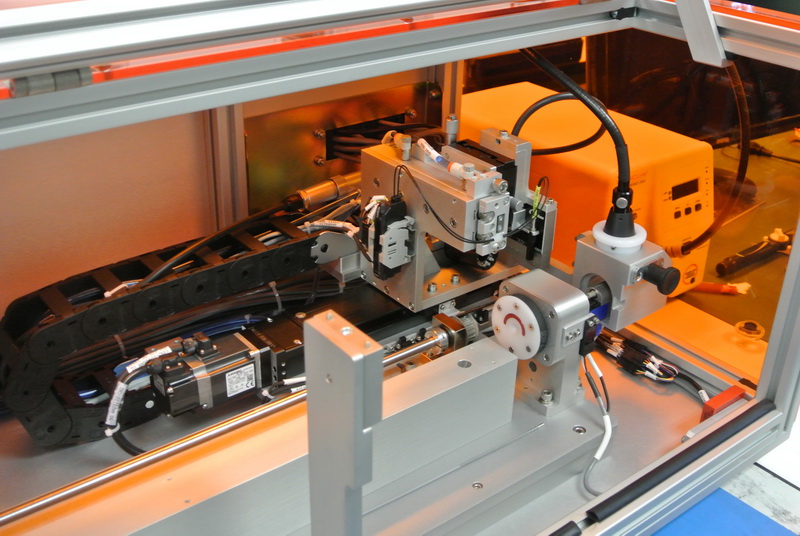

- Islands of Automation

An island of automation is a fully enclosed system that has many automated steps within a single system. Islands are typically selected for a sequence of difficult operations or to target higher throughput. An example would be conveyance system with adhesive dispense, part placement and UV cure all in one system.

- Fully Integrated line

The fully integrated line is what you imagine when you think production without any human intervention. Suitable for the highest throughput production processes. One machine leads to another for seamless integration. The disadvantage of the fully integrated line is in its inflexibility. A break in the process step will lead to systematic delay in production.

At Owens Design, we’ve well-versed in helping our customer identify the right amount of automation required to reach their required ROI. Contact us with your application at sales@owensdesign.com.