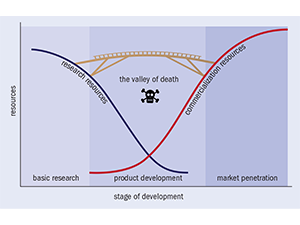

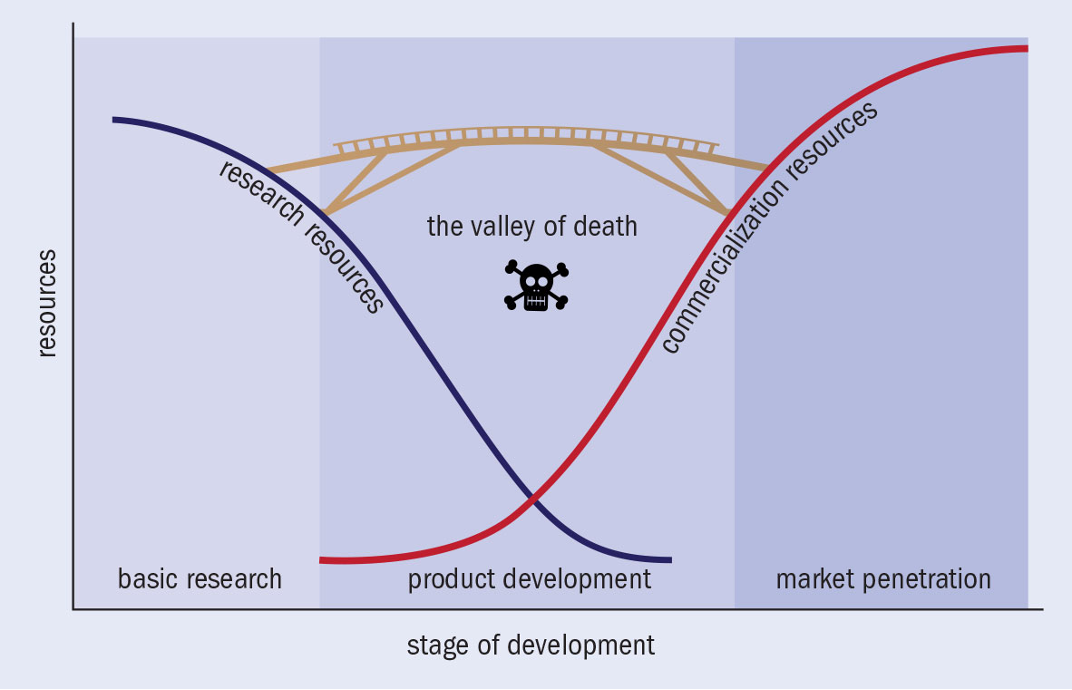

How to Get Your Technology Manufacturing Startup Across the Valley of Death

The startup journey can be a perilous race to transform your lab-scale idea into a market-ready product and includes significant hurdles. The most notorious is the so-called “Valley of Death,” from which many manufacturers never escape – but there is a way to bridge the valley to penetrate the market and achieve success.

Crossing the Valley of Death in Manufacturing

For OEM and manufacturing startups, the Valley of Death is the period between a product’s initial development – encompassing costs for research, development, prototyping, and production – and when the product begins to generate consistent revenue.

During this phase, organizations grapple with a variety of risks, including cost overruns, inadequate resources, and challenges with operational scalability.

Notably, a Startup Genome study found that nearly 70% of startups scale prematurely, a pitfall that OEMs should also heed as they introduce new products. Missteps in this stage often result in increased inefficiencies, and in some cases, business failure.

With diligent processes and a strategic approach, these risks can be minimized. Here are a few strategies for getting your startup over the drop.

Keys for Bridging the Valley of Death for OEMs & Startups

Strategic Planning

A comprehensive understanding of the business model, the unique value proposition, manufacturing processes, intellectual property (IP), and long-term vision for the project are vital. In addition, preemptive risk assessment, robust supply chain management strategies, and preparations for market volatility can fortify entities against potential turbulence.

Concept Identification

Before rushing to scale, validating the manufacturing concept is essential. This can be referred to as the feasibility stage of product development and involves identifying critical requirements for the project, from design elements and functional specifications to technical parameters. Responsiveness to market trends and consumer feedback can ensure your strategy remains dynamic and adaptable.

Design & Build

Creating a cost-effective, efficient and market-ready product design is key to the success of any manufacturing endeavor. The integration of regular progress reports, stringent quality control, and feedback mechanisms help ensure alignment between product development and market needs.

Production Models

Depending on the nature of the project and the resources available, startups can consider various production models, including self-production, contract manufacturing, and build-to-spec outsourcing. Each model presents its own benefits and challenges:

Option 1: Do-It-Yourself (DIY)

DIY production requires a hefty investment of money, time and focus. Additional non-production resources will need to be hired to support manufacturing from engineering to operations. Additional manufacturing space, perhaps another building, will also be needed.

Option 2: Contract Manufacturing

Contract manufacturing is a commonly used outsourcing model employed by companies to scale production and reduce overhead. While it can provide a cost-effective way around scaling obstacles, contract manufacturing is not the right fit for every project and when it is wrong, it’s often really wrong – with results that quickly reverse any cost savings.

Option 3: Build-to-Spec Outsourcing

For highly complex, unique and specialized projects that don’t meet the criteria for successful contract manufacturing and may require ongoing design services, you may benefit from “build-to-spec” manufacturing outsourcing. Contract manufacturing puts the responsibility for specifications onto you while build-to-spec outsourcing encompasses design improvements and the completion of any missing documentation.

Partnering for Success: The Advantage of Outsourcing

Navigating the treacherous Valley of Death requires not just strategic foresight, but also the backing of experienced partners. Startups and OEMs often grapple with challenges such as high overhead costs, resource constraints, and a lack of specialized knowledge required to transform their innovative ideas into market-ready products. In such scenarios, outsourcing emerges as a strategic solution, offering a cost-effective route to access specialized skills, enhance production efficiency, and stay focused on core competencies like product innovation and market expansion.

With over 40 years of expertise in providing design, engineering, and manufacturing support, the Owens Design team offers a valuable partnership to both startups and established OEMs needing design and manufacturing support.

Owens Design collaborates with your organization, extending your engineering team and transforming your IP into scalable production – from lab to fab in months vs. years. For factories needing custom automation solutions, Owens Design bridges the gap between R&D and manufacturing by automating manual processes and rapidly scaling production.

A successful partnership is more than a transaction. It’s a collaboration with a trusted partner who understands your vision, aligns with your goals, and is equipped to tackle the inherent complexities in your journey from lab to fab. With Owens Design, you are not just mitigating risks, you’re also fast-tracking your growth by leveraging proven expertise and a commitment to your success.

Speak with the Owens Design product development experts to turn your innovative ideas into market-ready products you can traverse the Valley of Death.