How to Select a Custom Automation Solution Partner

In our Off-the-Shelf (OTS) Equipment Suppliers blog – part of our How to Find the Right Custom Manufacturing Equipment Partner series – we discussed how OTS might be the right fit for you as the fastest and least expensive option.

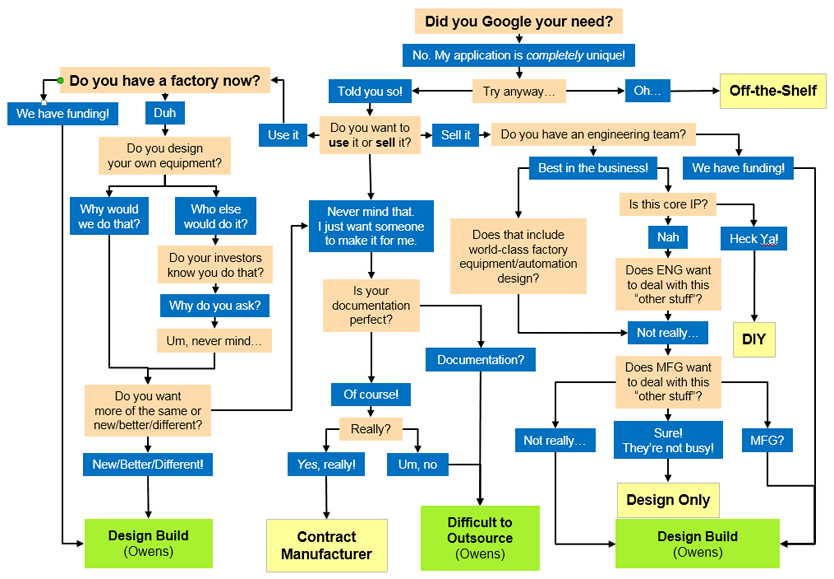

When there isn’t an OTS option, however, it’s time to determine how to get the custom machine that fits your needs based on what type of customer you are.

Business Focus

There are two types of customers with custom manufacturing equipment needs:

- Original Equipment Manufacturers (OEMs): customers for whom the factory equipment is their product, including companies that sell process or metrology equipment based upon specialized technologies or intellectual property (“IP”)

- End-Users: customers for whom the equipment is for making their products, which is anyone who operates a factory; the equipment that fills the factory either came from OEMs or some flavor of custom equipment supplier

It’s not unusual for one company to be both so, when searching for a custom equipment supplier, the first thing to determine is which kind of customer you are for the equipment you need.

For End-Users

End-user manufacturers are those who use factory equipment as a means to an end: making products. The equipment does not need to be fully optimized; it just needs to work. End-users want safe, reliable and inexpensive equipment – but in the end, low ongoing operating costs, a.k.a. total cost of ownership (TCO), is what really matters.

Metrics such as cost per unit over the equipment lifetime, or return on investment (ROI), are paramount. Any distinction between non-recurring engineering (NRE) to design or integrate the system and the cost of the system itself is often irrelevant. The net cost to get the system is all capex and all goes into cost of goods sold (COGS) as depreciation.

For many end-users, the parts being handled are what’s unique, not the process per se. For customers who are not differentiated by their manufacturing technology, good enough is, well, good enough. If the process isn’t complex and looks don’t really matter, the best choice may be the lowest cost supplier you trust to get the job done.

For typical handling and assembly applications, systems integrators may be a good choice because they have a portfolio of components and sub-systems that can be inexpensively tweaked and integrated to perform almost any assembly manufacturing task.

If the process is truly novel or challenging, most systems integrators lack the specialized skills and capabilities to incorporate the process. A lower risk approach will be to work with a custom equipment company that has knowledge of similar processes and experience in integrating innovative processes.

For OEMs

OEMs are those who will “sell it” so the strategy is different and often fits well with the business model of custom equipment suppliers. The system is the product (or part of it). NRE and unit cost are different things and need to be treated separately. NRE is a one-time development cost and assuming a healthy volume of sales is not all that important. As we discuss in another blog post, at almost any price, NRE is less expensive than hiring, training and sustaining a suitable engineering team yourself. Heck, NRE may even be a tax-deductible R&D expense…!

The unit cost, however, goes directly into the product COGS and gross margin. This matters a lot. OEMs are often willing to spend more on NRE to get the lowest possible unit cost, a more attractive system, better performance, or a finely optimized design. For OEMs, the following are crucial:

- Vendor design and manufacturing skills

- Ability to ramp (up and down) with your needs

- Compatibility with the internal product design teams

- Knowledge of the OEM’s industry requirements is crucial

OEMs differentiate on the performance (hopefully not just the cost…) of their product. It isn’t acceptable to have part of their precious product be “merely OK.”

OEMs see the value of engineering expertise and flexible manufacturing prowess, and an ability to execute and refine prototype and pilot builds. Custom “design and build” firms that have the right skill and experience with the OEM’s industry often make a lot of sense.

If all goes well, and after the design is stable, they’ll need the custom equipment supplier to ramp up production or help with the transition to a contract manufacturer. These are specialized skills and services “buried” in the NRE, and OEMs see the value in that. OEMs typically don’t have any need for systems integrators, unless they have assembly line needs, but in that case, they are an end-user.

Your Guide

End-users and OEMs have significantly different needs when searching for a custom factory equipment supplier. Knowing which type of manufacturer you are and your needs will simplify your final decision.

We’ve written a series of blogs introducing various manufacturing equipment options and the process for determining which is the best for you. Start with the first blog, or read the next blog: 5 Factory Automation Sourcing Best Practices.