So You’ve Discovered Lasers – Now What?

Author: Mark Turner, PhD, Turner Laser Systems

This is the first blog in a series to guide you through the key steps and challenges in laser process development — from concept all the way to manufacturing success.

This article focuses on the early phase where you’ve just discovered lasers as a potential solution for your product development and manufacturing needs. At this stage, you may be talking with your team to determine the best first step, and asking yourself “How do I evaluate whether or not laser is the right solution? What type of laser technology works best for what I want to achieve? How can I avoid going down the wrong path and causing unnecessary costs and delays?”

Whether you require a process for drilling, welding, cutting, dicing, marking, or scribing, it’s important to know how to choose the right partner to support your process and integration needs.

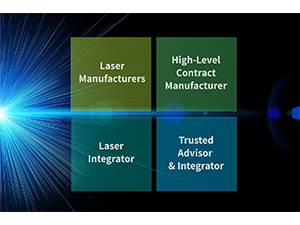

Laser processing enables a wide variety of applications, form factors, and materials leading to a confusing mix of solution providers in the marketplace. This article focuses on the four primary options to support your needs:

- Laser manufacturers

- Contract manufacturers

- Laser integrators

- Trusted advisors

Laser Manufacturer

Most customers begin with an online search. They often end up reaching out to a laser manufacturer to determine if one of the manufacturer’s lasers would be suitable for their needs.

Laser manufacturers are a great resource and repository for generally pairing the types of lasers to the types of materials and processes. It’s important to understand that laser manufacturers don’t give you a complete vision and foresight to how a particular laser will be integrated into a manufacturing solution. Without that foresight, customers are left uncertain in the practicality, viability and return-on-investment of the lasers in the product development stage as well as the turnkey manufacturing phase.

Also, depending on the complexity of the process required, laser manufacturers may not be able to make your complete test part with the features you require. For example, laser manufacturers are excellent at producing one beautiful laser-drilled hole but may struggle to provide you a full size wafer with an array of accurately positioned holes. That type of work requires a lot more development time, custom fixtures, and automation capability.

Contract Manufacturer / Job Shop

Some customers are not initially concerned how the products are made but just getting the product made. In this case, customers might provide a part drawing and the material spec to a contract manufacturer (CM) to make those parts.

The nice thing about CMs is that they are very well versed in manufacturing to design spec, and will do everything from laser cutting to post-processing. They’ll work out the nitty-gritty behind the scene so you are presented with (hopefully) a good part. They can be an excellent solution to get a processed part into your hands quickly, so you can prototype your product and see if laser processing can be possible. Keep in mind that just because a CM says “no bid” (i.e. they won’t do it) doesn’t mean it can’t be done!

A downside of going to a CM, however, is that you can end up with a beautiful part but have no idea how that part was made. Without that knowledge, you can’t determine if the process and the technology behind making that part is scalable, and how to integrate this technology into your manufacturing if you want to internalize that production within your company. This may become a black-box solution where you lose control on pricing and schedule. And if you’re in the medical industry, it can become even more troublesome to have additional documentation from a third-party supplier.

So, there are definitely pros and cons of going to laser manufacturers and contract manufacturers, and there’s definitely a time and place for doing so.

A Quality Laser Integrator

The right solution also needs to meet your manufacturing requirements. We often recommend that you work with highly knowledgeable laser systems integrators: someone who thoroughly understands how to pair a variety of lasers to your processes and materials, while possessing depth of knowledge on precision motion and factory automation. Such integrators, like Owens Design, provide a big-picture perspective, and can work out a right solution for your application from a product development and a business standpoint.

An experienced laser integrator will not only bring you the right laser and beam delivery for the process, but provide part alignment, material handling, and robotic automation. They will additionally deliver controls and software which is critical to the success of the technology integration. The need for intuitive and effective software for controls is sometimes overlooked and can be a significant cause of unexpected delays and costs.

This overall solution should enable a seamless and smooth transition between all the stages of your product development:

1. Early R&D phase

2. Testing out several batches of products to evaluate quality, repeatability and yield

3. Integration of a first laser machine into your facility (i.e. pilot line)

4. Scaling up with more systems (if required)

A Trusted Advisor

More importantly, ask your supplier if they are willing to educate you throughout this process. Frequently, lasers are seen as a black-box mystery in the world of laser physicists, causing customers to believe they have to just trust the information on the datasheet or a laser sales rep. This can be a very risky approach! Many product manufacturers want to work with a supplier they can treat as a trusted advisor and build a collaborative relationship.

Such a partner will seek to understand your various challenges and your end goals in order to develop a solution that maximizes your ROI. Sharing relevant information in a collaborative way that educates on both parties delivers the best outcomes and explores what’s important from a technical, manufacturing and business perspective. Using this perspective, we collaboratively develop the most valuable solution and guide our customers to manufacturing success. To ensure a holistic solution, it’s important to understand how these technologies work—why specific lasers or beam delivery systems and lenses are chosen; how the laser solution can scale up from manually loaded systems to robotic loading in fully automated systems. The goal is to provide you the knowledge you need to confidently adopt the technology, and can, in turn, educate your own technical teams on the new technology being onboarded.

Each solution provider has its own benefits and disadvantages. Below is a general comparison chart for determining the best laser processing partner for your manufacturing needs during that very early stage of product development:

If you’ve confided in one such advisor already, you’re in good hands. Otherwise, note that searching for and establishing a trusted advisor to support you early on is going to pay dividends. If you’re completely new to laser technology and the search feels daunting, here are some good indicators you’re talking to a potential trusted advisor:

- They’re an expert in the field of laser technology

- They’re a knowledgeable laser integrator with a good understanding of precision automation and manufacturing

- They have the ability to listen and understand your needs (including your return-on-investment) and challenges

- They provide unbiased feedback

- They communicate openly and welcome feedback

- They collaborate and are willing to educate and share knowledge

Get Started Today

Please contact us for answers to your questions about laser systems, laser processes, or anything related to laser manufacturing. We’ll be happy to educate, share information, and point you in the right direction.

In the next blog, we will share tips and info in determining the right laser for the job.

Contact us to learn more about custom lasers

Article reprinted with permission from our partner Turner Laser Systems