Time to Scale: When Should You Use a Contract Manufacturer?

Congratulations: your product is a hit and the time has come to scale up production with replicable results. As an OEM, your product is selling and it’s time to ramp up. As an end-user, your product is flying off the shelves and you need to rapidly scale and automate your manufacturing to meet demand.

So, you call up your procurement manager and tell them to build you a bunch of new machines. They write a 200-page RFQ, send it to all the usual suspect contract manufacturers (CMs), and collect beautiful color proposals as they come in, filled with graphs showing amazing volume pricing.

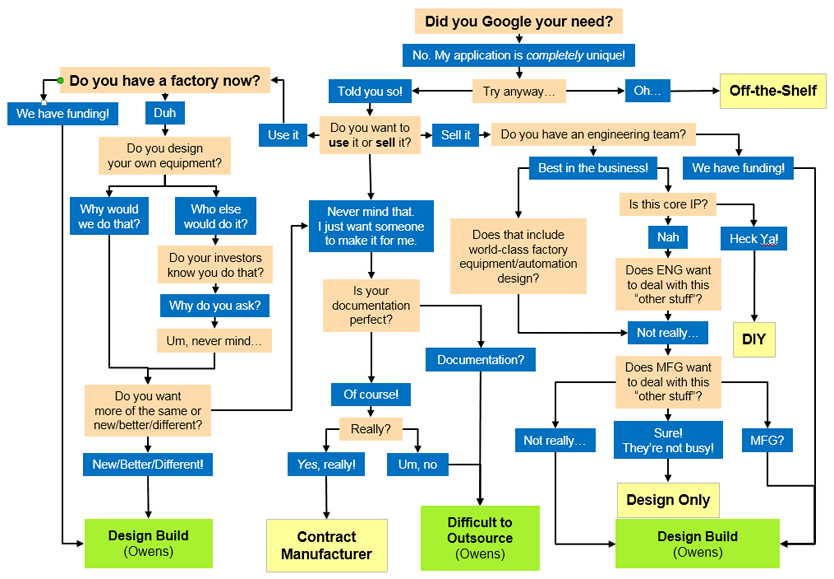

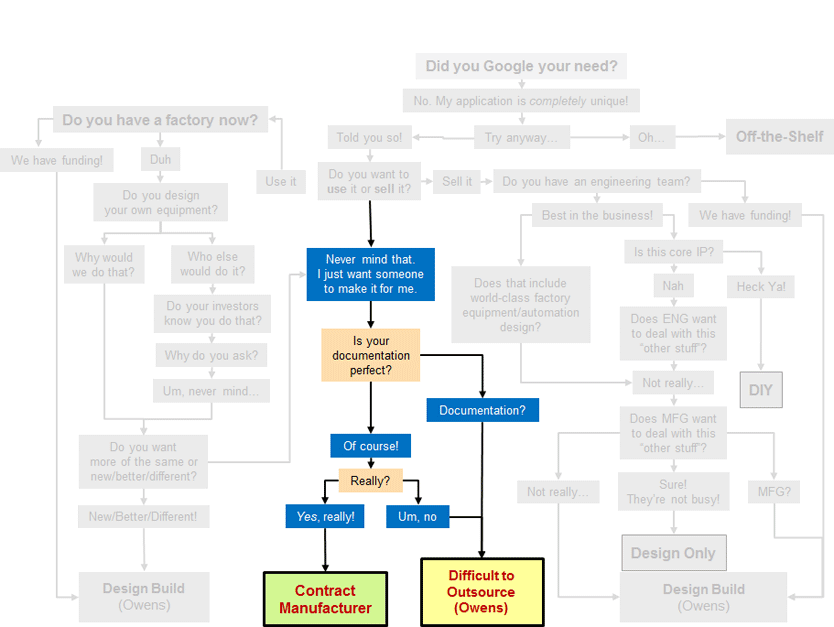

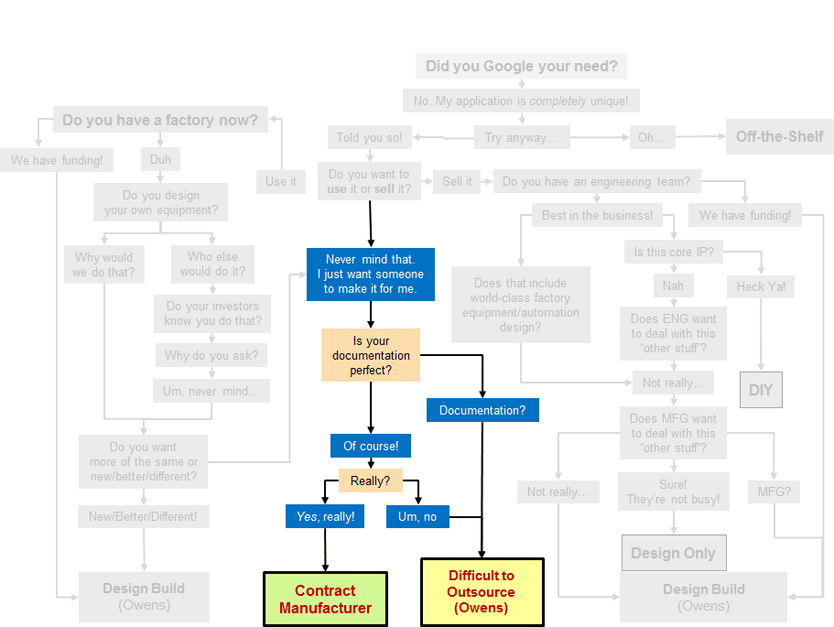

There’s just one problem: there’s a time to use CMs and a time to avoid them, so how do you know which is which?

When You Should Use a CM

CMs can be cost effective, but those low prices come with caveats that can ruin things if you aren’t careful. True, low-cost contract manufacturers are perfect if, and only if:

You Need a Large Volume of Machines

Missing the order quantities will cost you. Missing by a lot will cost a lot, or they may walk away from the business. CMs depend on volume and on accurate forecasts for their cost model to work. Mucking with those things can cause the wheels to come off pretty quickly.

Your Machines Are All Identical

Variations cost extra. Changes cost a lot extra, if they can be handled at all. These things also cause delays and incur extra costs for re-stocking and scrap.

Your Documentation Is Perfect & Validated

A CM will build exactly what you tell them to build—whether it’s right or not and whether it works or not. Any CM can, and will, do some cleanup and refinement of your documentation so they can build your systems most efficiently within their systems and processes. But it’s not their job to second guess your documentation, your design, or your functional intent, so it’s garbage in… garbage out.

You Have Optimized the Equipment Design for Cost

A CM may charge a slightly lower margin than a design and manufacturing firm. This cost savings often pales in comparison to the savings you can gain by optimizing the design for cost. Depending on the ratio of material to labor, redesigning for cost can yield a 10%-40% cost reduction. If cost is critical, consider first optimizing the design for cost before transferring to the lowest cost supplier.

When CMs Are Not the Answer… or Just Not Yet

A CM is simply not appropriate in all cases. In some instances, your equipment may not be ready for a CM to tackle. In these cases, a design and build firm is needed to complete the engineering work (all the engineering work) and get through pilot builds to wring out all the gaps in the design and documentation.

If you have continuous improvement program (CIP), you may need a firm that can develop those changes and get them into the design and production seamlessly and painlessly. Despite your best efforts to push back, your customers will likely require you to customize your equipment to their special needs.

Design and build firms like Owens Design that have expertise with difficult outsourcing projects (DtO as we call them) can take equipment and projects with all kinds of issues that stump CMs, and turn them into successful outsourced builds. Some examples of issues they can handle:

- Build documentation is incomplete, untested, inadequate or completely non-existent

- Historical builds with broad assumptions as to what constitutes open stock (ex. techs know when to drive to the local hardware store to get plumbing hardware…)

- Legacy products with obsolescence issues, including in the documentation formats

- Incomplete designs or designs that require fixing or upgrades

- The equipment has never undergone a proper transfer to manufacturing (NPI, AME) or validation via a controlled build

- The build/setup/debug/test requires technical or engineering expertise, or internal machine shop capabilities

- The one and only person who actually knew how to build it retired years ago and now lives in a memory care clinic in Sarasota – maybe you’ve heard the local Silicon Valley legend about the old guy and the anodization process?

Your Guide

Owens Design specializes in building equipment with these sorts of issues and can clean everything up to the point where they can repeatably build the systems in volume at low cost. We will collaborate with you to redesign for lower cost and add or remove features. If appropriate, we can even help you transfer the build to a CM for high volume production in a low-cost region.

In summary, if CM is the right solution for you, take the time to evaluate your readiness. If you aren’t sure if your equipment is ready for CMs or you realize your need help getting ready, work with a trustworthy custom build design firm. The investment upfront will prove to be well worth the effort in a long run.

We’ve written a series of blogs introducing various manufacturing equipment options and the process for determining which is the best for you. Start with the first blog, or read the next blog: How to Select a Custom Manufacturing Equipment Partner.