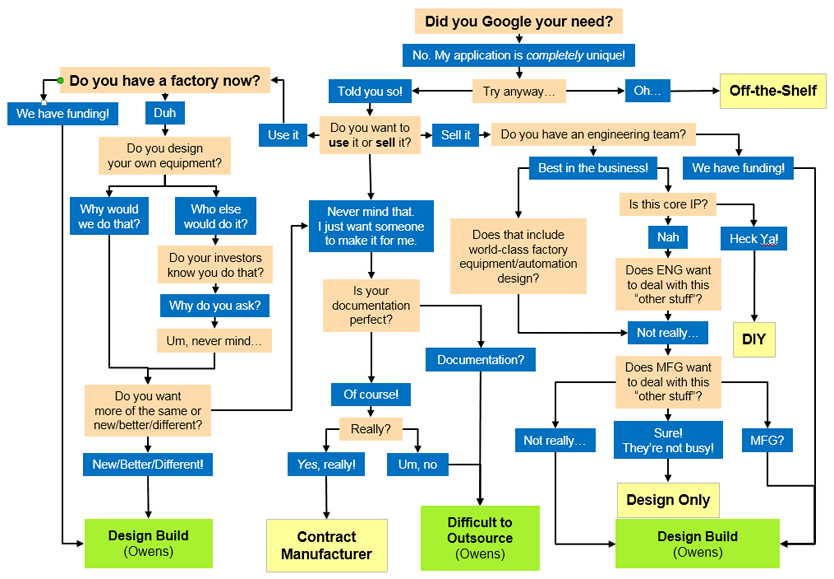

Why OEMs Should Outsource Product Development & Manufacturing

If you are an OEM, you already have great engineering and manufacturing; why would you outsource anything? This blog lists three reasons that OEMs should consider outsourcing.

1. Focus on What You Do Best

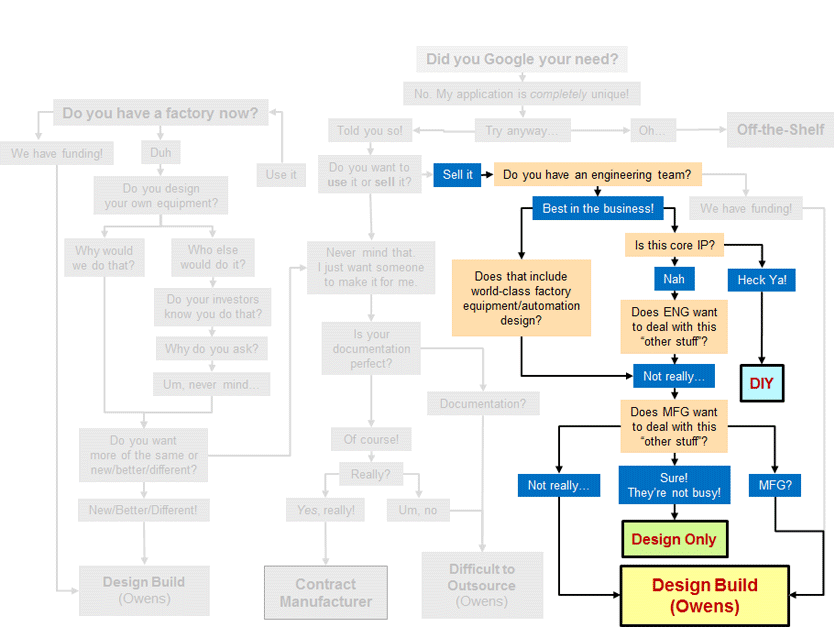

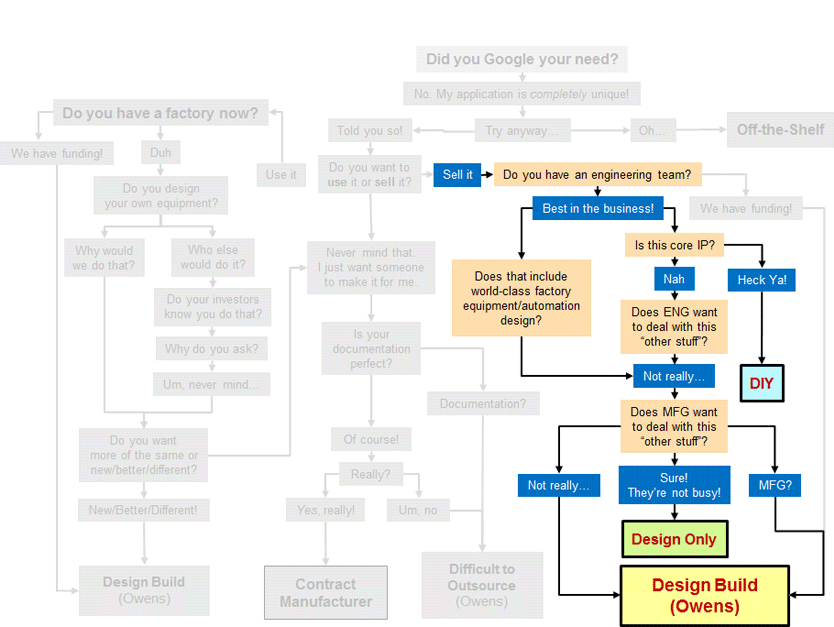

Your differentiation is your IP and that’s what customers value. That is what you must do and do well.

But factory equipment is not just the interesting bits – it also includes material handling, environmental controls, air and fluid handling, frames and skins, and all that “other stuff” in the platform. Sometimes there are also peripheral pieces of equipment or modules, like loaders, dryers, heating and cooling stations, and other things necessary for your product but not part of your differentiation.

As an OEM, should you tie up your capital to develop, train and retain engineering and manufacturing resources and expertise for these platforms and peripherals? Once you build such a team and complete the design, can you keep them engaged and busy? Can you retain the best employees? More to the point, is a world-class platform team a strategic asset, or an expensive distraction? And if it’s not world-class, are you giving up competitiveness?

Factory equipment design, even for platforms and peripheral equipment, is a specialized skill. If you need that skill, hire it only when you need it and for only as long as you need it, while focusing your energies and resources on doing what you do best: making your IP even more compelling.

2. Go Faster with an Expert

An in-house team may make sense for large OEMs with multiple product lines to effectively leverage a platform team. For small or specialized companies, especially startups, that doesn’t work so well. Do you only need to design a platform once, or are your sales sporadic (ex. build-to-order)? Maybe your customers demand sophisticated platforms (ex. semiconductor fabs) and you couldn’t acquire that expertise in any reasonable time, or cost, even if you wanted to. In such cases, leveraging outside resources is really the way to go.

3. Find the Right Partner

As for selecting an engineering and manufacturing outsourcing partners, trust is critical. As a knowledgeable OEM, you might be able ensure a successful outcome without trust using brute force with a massive spec and stacks of legal documents. But a legal remedy after a poor outcome isn’t all that helpful. At the end of the day, the engineering team needs to have the depth and breadth of talent and specialized knowledge to ensure a successful design. The manufacturing team has to be adept at assembling and bringing up equipment that has never existed before, and doing so in a way that produces reliable, replicable equipment.

Your partner must also mesh smoothly with your internal teams to ensure that both sides understand what each other needs, and can speak candidly about concerns, ideas and issues. The firm should be willing and able to act as a “trusted advisor” and select the best possible solution, whether or not it means a project for them today. These practices are what create trust.

A skilled design and build company with deep knowledge of your market will create the platform you need, even if it doesn’t look like what you originally asked for. They will carry you through, at a minimum, through pilot production, cost optimization and often even ongoing volume production depending on your cost and volume targets. Ideally, they should also be able and willing to help you transfer mature designs to an appropriate contract manufacturer (CM), when the time is right. Your supplier should act like part of your team with a business model that provides mutual benefits for both companies.

Your Guide

OEMs that partner with an experienced engineering and manufacturing outsourcing partner can accelerate the design and manufacturing of the platform and focus more on developing their critical IP.

This is the last in our series of blogs introducing various manufacturing equipment options and the process for determining which is the best for you. Start with the first blog, or read our last blog: Dear Startups: Manufacturing Equipment is Not for DIY!