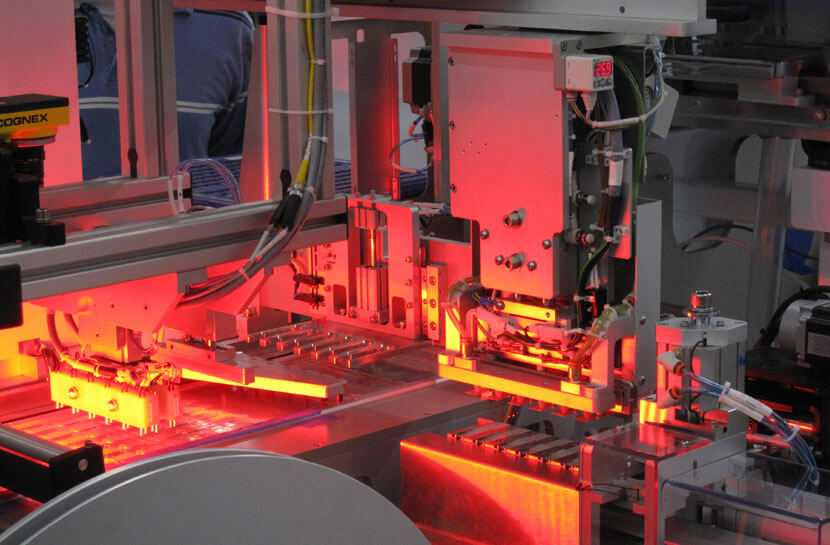

Why Have Owens Design Manufacture Your Engineered Design

I recently had a thought-provoking conversation with a senior executive from a leading semiconductor equipment OEM. During a discussion on business strategy, I asked this longtime customer how he would describe Owens Design to his peers. His response was “an excellent engineering company that insists on manufacturing.” Although I had never expressed it quite that way, he was right. We do “insist” on manufacturing our designs. In fact, we believe that manufacturing our designs sets us apart from other engineering firms and is a critical element to being successful in this business. There are three key benefits to integrating design and manufacturing for low-volume, complex capital equipment.

Reason #1: The first reason we manufacture our designs is that it makes us better designers. One of the unique challenges in the capital equipment business is the combination of high systems complexity with low manufacturing volumes. We have all experienced designs that are virtually impossible to manufacture, ultimately leading to unpredictable schedules, excessive rework and high costs. Due to low manufacturing volumes, there isn’t time to “get it right” in manufacturing. It has to be done right in the design stage. Having design and manufacturing teams in the same location is critical to reducing this problem. While you might assume the design team would be more productive if they weren’t required to deal with manufacturing issues, it is actually quite the opposite. The development team must have an understanding of the kinds of problems faced by manufacturing. Ultimately, the design team is responsible not only for getting the designs manufactured, but for resolving issues along the way in order for their next design to be better. Some of the issues that can come up include manufacturability, cost, reliability, cleanliness and compliance. This is one of our key company philosophies and explains why we have a reputation for practicality. The concept is simple; if you know you are going to have to build it, you will do a better job designing it in the first place.

Reason #2: The second reason we manufacture our designs is because it makes the development programs run faster. Not just a little bit faster, but a lot faster. We can significantly compress the prototype development cycle by overlapping design and manufacturing tasks. We can also compress the beta to pilot transitions resulting in faster time to both production and the field. One of the most difficult aspects of any program is managing the transitions from prototype to beta and beta to pilot. In each of these transitions, there is not only a hand-off of technology, but also a hand-off of leadership. Having the design and manufacturing organizations separate or, even worse, in different companies, compounds the problem. Most companies struggle with making their internal new product introductions run smoothly. Dividing these responsibilities only makes an already complex problem even more difficult.

Reason #3: The third and most important reason we manufacture our designs is that it results in a higher level of customer satisfaction. It provides the customer with a single point of accountability to take care of issues such as cost, performance, reliability and safety. If the product fails to meet any of the criteria, we are responsible for making it right. No finger pointing between the design and manufacturing companies. Whatever the problem, we are responsible for meeting our commitments. The result is a considerable reduction in risk and headaches for our customers. One common example is the COGS target (cost of goods sold, i.e. the total manufacturing cost, including materials, labor and overhead). Virtually every product requirement includes a COGS target. The development team must deliver a design that can be manufactured to the forecasted quantities in order to meet the COGS target. To do this, the development team must understand the manufacturing strategy and manufacturing costs. They must know in what volumes materials will be procured and from which suppliers. Understanding the impact of quantity roll-offs is important with low-volume manufacturing because fabricated parts vary significantly in cost depending on the quantity ordered. For example, a sheetmetal part that costs $100 for a quantity of 10 may cost $400 for one. Labor costs also depend on build quantity, but will depend more on the learning curve and manufacturability of the product. If the development team doesn’t know the cost roll-offs for fabricated parts or the labor hour roll-offs based on the phase of the program, the risk of missing the COGS target is very high. We all know too many cases where the design ends up costing double or triple the expected cost. This can either kill the program outright or spawn a cost reduction project; an expensive result in either case. Managing the COGS target is a complex process and, in order to achieve optimal results, it must be approached from an integrated design and manufacturing perspective. Dividing the responsibility between companies can result in a subpar product. A similar argument can be made for other critical product requirements such as performance, reliability and manufacturability.

At Owens Design, we are more capable of satisfying our customers if we manufacture our designs. We can ensure that all expectations are met, including those that creep in as the product goes into production. And satisfied customers stay with us for a long time, bring us more business and may even refer us to their peers.

Manufacturing our designs is an essential element of our business. It results in better designs, faster developments and an improved customer relationship. Obviously not every product fits this model, just as every product is not suitable for outsourcing. For low-volume, complex capital equipment, integrating design and manufacturing is the right approach.