CASE STUDIES

Mobile Device Assembly Line

Situation

Mobile device manufacturer needed to quickly ramp production for new product while accommodating expected process changes.

Problem

The device required precision optical alignment, complex assembly operations, and extensive testing. Manual assembly was not an option.

ODI Role

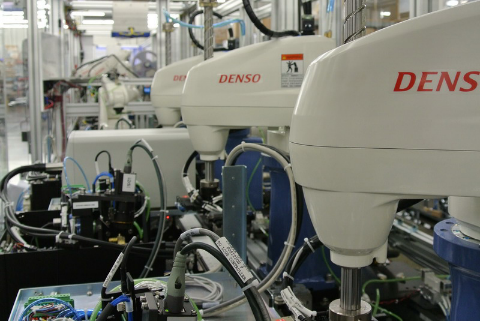

Developed and built assembly line in 26 weeks incorporating 36 process stations, 24 robots, 29 inspection / alignment cameras, and 19 computers. Machine architecture allowed for rapid changes to support process development.