CASE STUDIES

PV Cell Handling Automation

The Situation

Solar concentrator startup needed to automate Photovoltaic (PV) cell handling and inspection into a manual process tool.

The Challenge

PV cells are thin and fragile. Automated vision is required to verify cell quality and location for cell positioning. The system must handle (and dry) wet cells at the output of the process.

The Solution

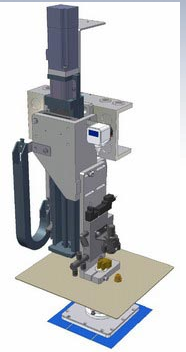

Owens Design developed an automated PV cell handling system with vision inspection and factory automation software. They worked collaboratively with the customer to develop a cell drying system to meet the targeted throughput without damage to the cells. The system was capable of picking up and drying thin ( < 200µm ) PV cells in wet or dry condition.