CASE STUDIES

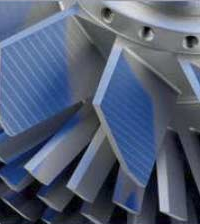

Solar Vacuum System

As the solar photovoltaic market continues the drive to higher volumes and lower costs, the demand for custom high vacuum (HV) equipment is dramatically increasing. Successfully developing a high productivity, high reliability, factory ready HV system requires the integration of many specialized skills. Owens has developed a deep expertise in vacuum chamber design, vacuum mechanisms, thermal management, and vacuum system manufacturing through the design of many HV systems.

Vacuum System Design

Owens’ approach begins with a clear understanding of our client’s process requirements, throughput, and factory layout. Once the best concept is selected, the detailed system design including vacuum requirements, thermal management (heating and cooling), and motion control is completed. Our experienced vacuum engineers work closely with our client’s process engineers to identify cost, performance, and throughput trade-offs. After the design is optimized, each sub-system is detailed including the chamber, pumping, mechanisms, electrical controls, and software.

System Manufacturing

Owens works with our expert suppliers to cost effectively fabricate the vacuum chamber, piping, and precision mechanisms. Once all of the material has been acquired, our skilled technicians perform the assembly of the vacuum system taking all required handling precautions to achieve a rapid bring up and pump down. In-house helium leak testing is performed to validate vacuum integrity and that the specified levels are obtained. All mechanisms, controls, and related features are fully tested prior to customer acceptance. A full set of design, manufacturing, and installation documentation is prepared to allow replication of the system for factory expansions.

SPECIFICATIONS

Markets / Applications

- Crystalline Silicon

- Thin Film (CIGS, CdTe)

- Semiconductor

- Ion Implantation

- Deposition (Sputtering, Evaporation)

Substrates

- Silicon Wafers

- Glass Panels

- Polysilicon Ingot

- Flexible Stainless

High Vacuum Design

- Vacuum level: Down to 10-8 Torr

- Leak rate: < 1 × 10-8 mbar × l/s

- Chamber Material: AL, SST (welded, machined block)

- Pump Selection: Roughing, Turbomolecular

- Valve selection: Gate, In-line, Angle, Butterfly, Pendulum

- Couplings: Electrical, Magnetic, Gas, Fluid

- Feed through: Dynamic seal, Fluid, Coaxial

- MESC Standard Interface Available

High Vacuum Mechanisms

- Precision Staging (X, Y, Z, Rotation)

- Linear / Rotary Motion / Robotic Integration

- Conveyors

Thermal analysis and management

- Heating: Up to 600° C

- Cooling: Water, Gas

Assembly / Test

- Integration / System Bring Up

- Pump Down

- Helium Leak Testing

- Heat / Cooling Uniformity / Ramp

- Functional test