Medical Device Manufacturing Equipment Design & Build

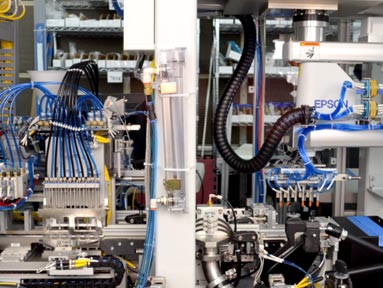

We design and build custom automation equipment used for the assembly and manufacturing of med-tech devices, with special emphasis on organic contamination control and chemical/materials utilization.

The goal is to enable your manufacturing competitiveness while ensuring confidentiality of your product and process innovation.

With over 40 years of experience, our custom designed and built equipment have a proven reputation for reliability and repeatability, with the ability to continuously verify and validate every process step. Some of our custom equipment project applications include:

- Precision dispense of low and high viscosity fluids

- Solid bead and powder reagent fill

- Aseptic environment compliance

- Precision alignment, orientation, feed, assembly

- High throughput robotic pick and place

- Ultrasonic welding, adhesion, bonding and lamination

- Defect inspection, sort, bin

- Labeling and verification

- Laser process development and integration

- Custom lyophilized bead handling and automation

Recent Projects

- Automated catheter tip radio marker ring sealing system incorporating pico jet dispense of 0.5nL, positional tolerance to 0.010”, UV cure and integrated video capture.

- IVD molecular diagnostics consumable metrology station for inline inspection of precision injection molded components, utilizing 2D and 3D cameras for dimension, flatness, and profile for critical surfaces.

- Automated electrophysiology patch clamp system manufacture and engineering upgrades for cost reduction and improved reliability.

- Lyophilized molecular diagnostic bead dispense system manufacture incorporating 4-axis SCARA robotics, machine vision, and part tracking.

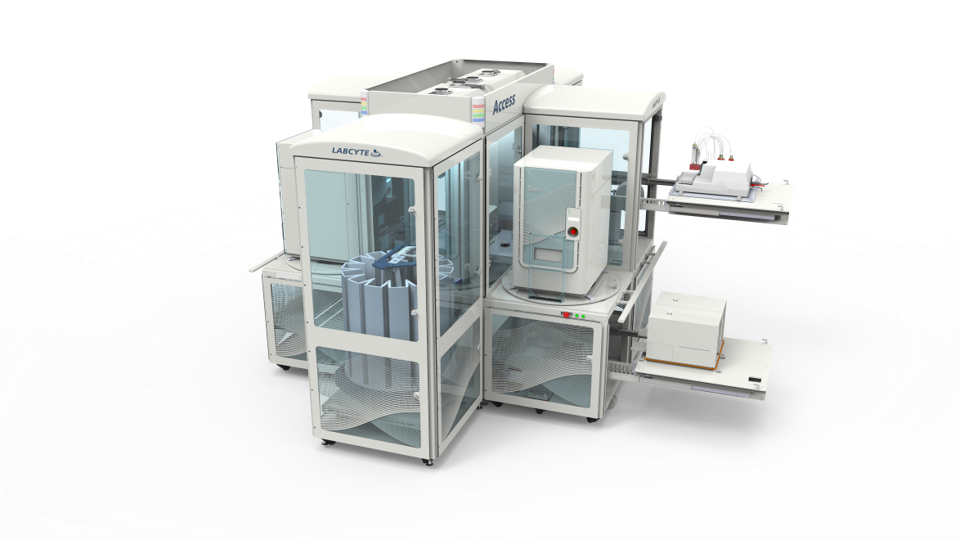

- Lab automation platform integrating customer specified devices for improving assay throughput and reproducibility. Incorporates environmental control, precision liquid handling, automated plate handling, inherently safe robotics, and field re-configuration.